No products in the cart.

Most people don’t give much thought to what’s happening under their car—until something goes wrong. That strange vibration at highway speeds, the sudden clunk when shifting gears, or the unsettling shudder when taking off from a stop could all point to a problem with one of the most critical yet often overlooked components of a vehicle’s drivetrain.

For Australians, this component is called a tailshaft—a term that makes perfect sense given its position at the tail end of the drivetrain. But in the US, it’s known as a driveshaft, which can create confusion when sourcing parts or discussing vehicle maintenance. And to make things even trickier, what Australians refer to as a driveshaft is an entirely different part—one that connects the differential to the wheels.

Understanding the differences between a tailshaft and a driveshaft isn’t just about terminology—it’s about knowing how power moves through a vehicle and what happens when things go wrong. Whether you’re an enthusiast modifying your car, a mechanic working on customer vehicles, or just someone trying to make sense of an online parts catalogue, getting it right matters.

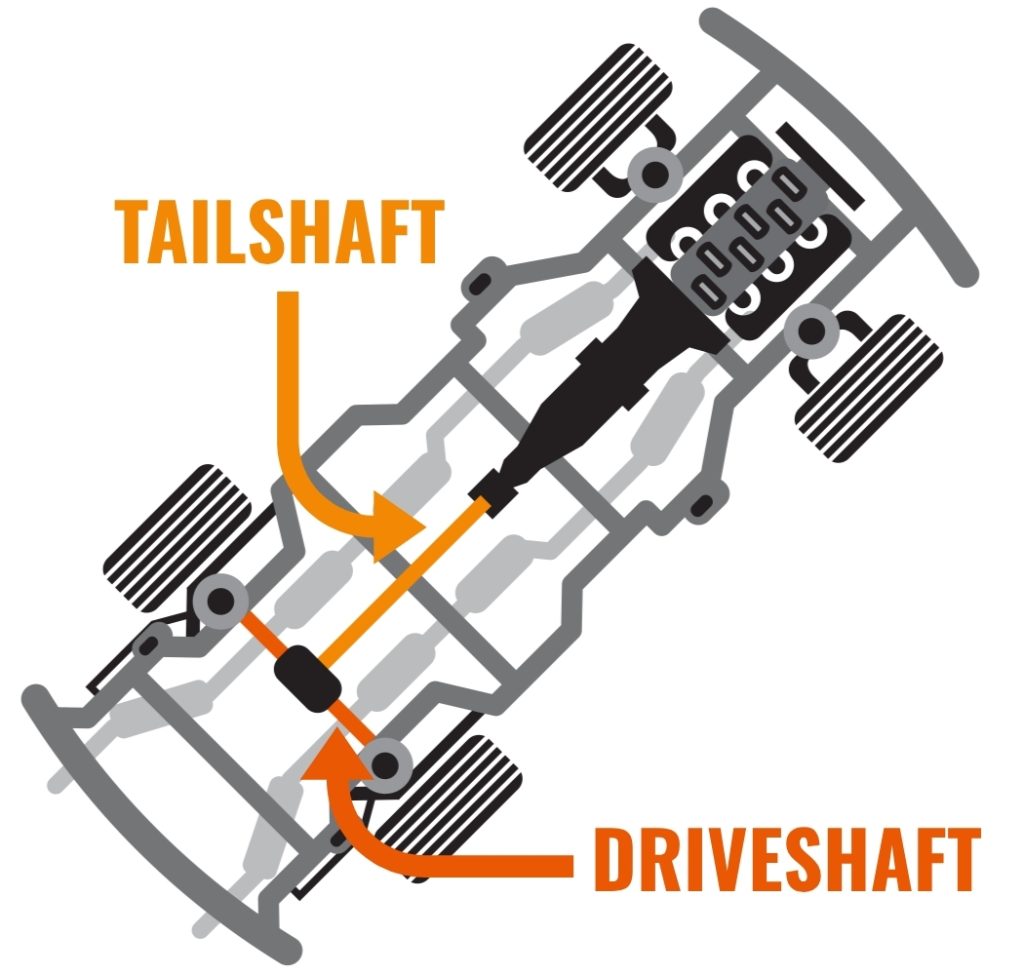

Before diving into the terminology debate, let’s first clarify exactly what these components do. If you look at the diagram below, you’ll see how a tailshaft connects the transmission to the differential, transmitting power to the rear wheels. This is a crucial part of rear-wheel-drive (RWD) and all-wheel-drive (AWD) vehicles, ensuring that engine power gets to the ground effectively.

Meanwhile, the driveshaft (in Australian terms) is what connects the differential to the wheels in vehicles with independent rear suspension (IRS). These shafts, often featuring constant velocity (CV) joints, allow the wheels to move up and down while still receiving power.

For Australians, the term tailshaft has been around for decades, but depending on where you are in the world, the name might not mean much. Across the Pacific, in the US, the same component responsible for connecting the gearbox to the differential is called a driveshaft. Different words for the same thing.

Here’s what creates a lot of confusion, especially when reading American sources. What we in Australia call a driveshaft (the shaft that transfers power from the differential to the wheels), over in the US they call this the axle shaft or half-shaft.

It’s more than just a case of regional slang. If you’re ordering parts, discussing repairs, or explaining an issue to a mechanic, getting the terminology right makes all the difference. The wrong word could see you waiting on the wrong part or misunderstanding a critical drivetrain issue. That’s why knowing how these components work—and what they’re called—matters, whether you’re an enthusiast fine-tuning your car or a driver just trying to keep things running smoothly.

| Component | Australian Term | American Term |

| Shaft connecting the gearbox to the differential | Tailshaft | Driveshaft |

| Shafts connecting the differential to the wheels | Driveshaft | Axle shafts / Half-shafts |

| Solid rear axle shafts (rigid axles) | Driveshaft / Axle shaft | Axle |

Understanding these differences ensures you don’t order the wrong part, especially when dealing with overseas suppliers.

A tailshaft is only found in rear-wheel-drive (RWD), all-wheel-drive (AWD), and four-wheel-drive (4WD) vehicles. It connects the transmission to the differential, ensuring power reaches the driven wheels.

In a two-wheel-drive (2WD) car, the driveline layout depends on whether it is rear-wheel drive or front-wheel drive.

In a four-wheel-drive (4WD) or all-wheel-drive (AWD) vehicle, the tailshaft serves a similar purpose but with added complexity. These vehicles typically have two tailshafts—one transmitting power to the front differential and another to the rear. In some cases, a transfer case splits power between them, ensuring proper torque distribution across all four wheels.

While the tailshaft handles power delivery from the transmission to the differential, the driveshaft (axle shaft) takes over from the differential, delivering power to the wheels. These shafts, equipped with CV joints, allow the wheels to move independently while maintaining smooth power transmission.

| Feature | Tailshaft | Driveshaft (Axle Shaft) |

| Location | Between gearbox & differential | Between differential & wheels |

| Suspension Type | Used in rigid axle setups | Found in independent rear suspension (IRS) |

| Joints Used | Universal joints (U-joints) or CV joints | Constant velocity (CV) joints |

A well-functioning tailshaft ensures:

Tailshafts are built from different materials, each with its own advantages:

A worn-out tailshaft can cause serious drivetrain issues. Some telltale signs include:

Ignoring these warning signs could lead to catastrophic drivetrain failure, so it’s worth checking if you notice any of them.

Understanding the difference between a tailshaft and a driveshaft is crucial, whether you’re working on your own vehicle or explaining it to someone else. In Australia:

Keeping your drivetrain well-maintained ensures smoother performance and prevents costly failures. Whether you’re after a replacement tailshaft, a custom-built setup, or expert advice, GJ Drivelines has the expertise to keep your car running at its best.

See the GJ Drivelines page “Tailshaft and Driveshaft FAQs for Every Car Owner”

https://gjdrivelines.com.au/tailshaft-driveshaft-faqs-car-owners/

Most people don’t give much thought to what’s happening under their car—until something goes wrong. That strange vibration at highway speeds, the sudden clunk when shifting gears, or the unsettling shudder when taking off from a stop could all point to a problem with one of the most critical yet often overlooked components of a vehicle’s drivetrain.

For Australians, this component is called a tailshaft—a term that makes perfect sense given its position at the tail end of the drivetrain. But in the US, it’s known as a driveshaft, which can create confusion when sourcing parts or discussing vehicle maintenance. And to make things even trickier, what Australians refer to as a driveshaft is an entirely different part—one that connects the differential to the wheels.

Understanding the differences between a tailshaft and a driveshaft isn’t just about terminology—it’s about knowing how power moves through a vehicle and what happens when things go wrong. Whether you’re an enthusiast modifying your car, a mechanic working on customer vehicles, or just someone trying to make sense of an online parts catalogue, getting it right matters.

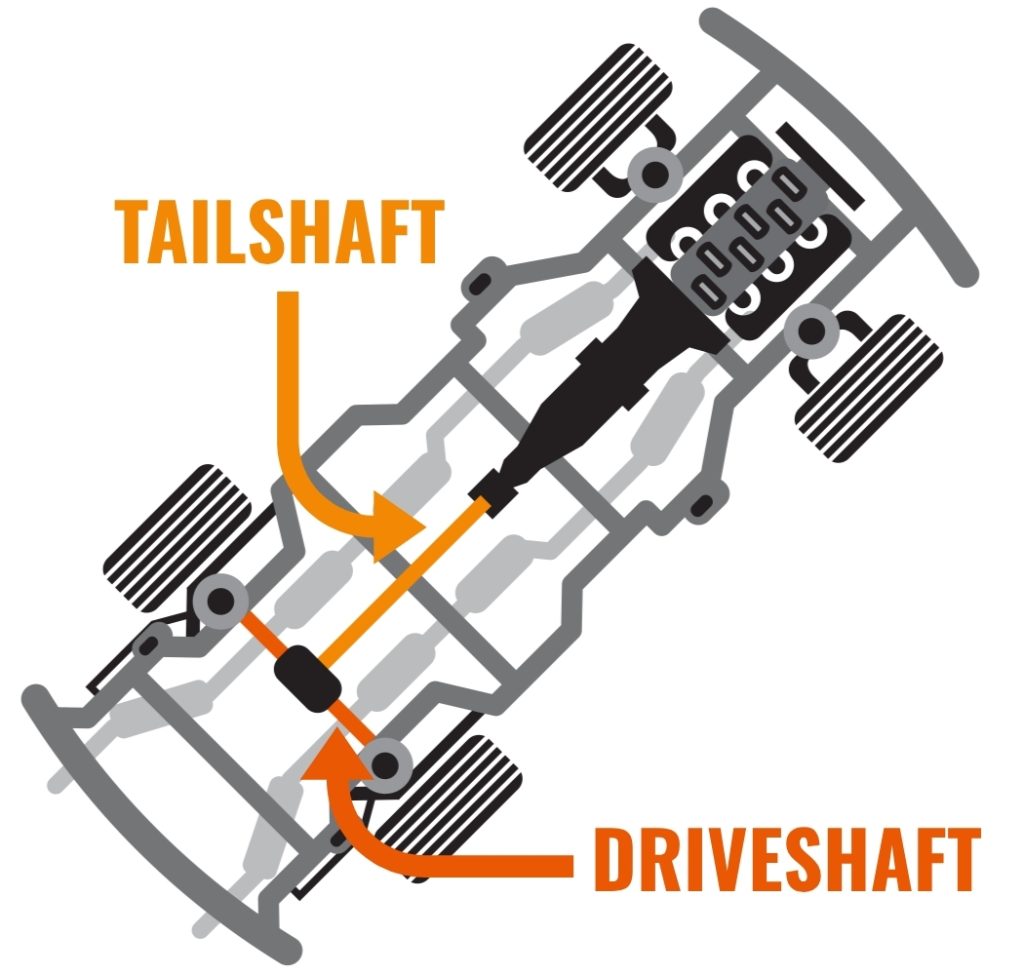

Before diving into the terminology debate, let’s first clarify exactly what these components do. If you look at the diagram below, you’ll see how a tailshaft connects the transmission to the differential, transmitting power to the rear wheels. This is a crucial part of rear-wheel-drive (RWD) and all-wheel-drive (AWD) vehicles, ensuring that engine power gets to the ground effectively.

Meanwhile, the driveshaft (in Australian terms) is what connects the differential to the wheels in vehicles with independent rear suspension (IRS). These shafts, often featuring constant velocity (CV) joints, allow the wheels to move up and down while still receiving power.

For Australians, the term tailshaft has been around for decades, but depending on where you are in the world, the name might not mean much. Across the Pacific, in the US, the same component responsible for connecting the gearbox to the differential is called a driveshaft. Different words for the same thing.

Here’s what creates a lot of confusion, especially when reading American sources. What we in Australia call a driveshaft (the shaft that transfers power from the differential to the wheels), over in the US they call this the axle shaft or half-shaft.

It’s more than just a case of regional slang. If you’re ordering parts, discussing repairs, or explaining an issue to a mechanic, getting the terminology right makes all the difference. The wrong word could see you waiting on the wrong part or misunderstanding a critical drivetrain issue. That’s why knowing how these components work—and what they’re called—matters, whether you’re an enthusiast fine-tuning your car or a driver just trying to keep things running smoothly.

| Component | Australian Term | American Term |

| Shaft connecting the gearbox to the differential | Tailshaft | Driveshaft |

| Shafts connecting the differential to the wheels | Driveshaft | Axle shafts / Half-shafts |

| Solid rear axle shafts (rigid axles) | Driveshaft / Axle shaft | Axle |

Understanding these differences ensures you don’t order the wrong part, especially when dealing with overseas suppliers.

A tailshaft is only found in rear-wheel-drive (RWD), all-wheel-drive (AWD), and four-wheel-drive (4WD) vehicles. It connects the transmission to the differential, ensuring power reaches the driven wheels.

In a two-wheel-drive (2WD) car, the driveline layout depends on whether it is rear-wheel drive or front-wheel drive.

In a four-wheel-drive (4WD) or all-wheel-drive (AWD) vehicle, the tailshaft serves a similar purpose but with added complexity. These vehicles typically have two tailshafts—one transmitting power to the front differential and another to the rear. In some cases, a transfer case splits power between them, ensuring proper torque distribution across all four wheels.

While the tailshaft handles power delivery from the transmission to the differential, the driveshaft (axle shaft) takes over from the differential, delivering power to the wheels. These shafts, equipped with CV joints, allow the wheels to move independently while maintaining smooth power transmission.

| Feature | Tailshaft | Driveshaft (Axle Shaft) |

| Location | Between gearbox & differential | Between differential & wheels |

| Suspension Type | Used in rigid axle setups | Found in independent rear suspension (IRS) |

| Joints Used | Universal joints (U-joints) or CV joints | Constant velocity (CV) joints |

A well-functioning tailshaft ensures:

Tailshafts are built from different materials, each with its own advantages:

A worn-out tailshaft can cause serious drivetrain issues. Some telltale signs include:

Ignoring these warning signs could lead to catastrophic drivetrain failure, so it’s worth checking if you notice any of them.

Understanding the difference between a tailshaft and a driveshaft is crucial, whether you’re working on your own vehicle or explaining it to someone else. In Australia:

Keeping your drivetrain well-maintained ensures smoother performance and prevents costly failures. Whether you’re after a replacement tailshaft, a custom-built setup, or expert advice, GJ Drivelines has the expertise to keep your car running at its best.

See the GJ Drivelines page “Tailshaft and Driveshaft FAQs for Every Car Owner”

https://gjdrivelines.com.au/tailshaft-driveshaft-faqs-car-owners/

Chrysler – Dodge

727 – 30 Spline 1 11/16″ Seal Diameter

904 – 26 Spline 1 9/16″ Seal Diameter

Ford

C6-T56 – 31 Spline 1 11/16″ Seal Diameter

AOD & C4 & T5 – 28 Spline 1 1/2″ Seal Diameter

4 R 7OW – 28 Spline 1.598″ Seal Diameter

General Motors

T-350 700R4-4LLOE – 27 Spline 1 1/2″ Seal Diameter

T-400-4L80E – 32 Spline 1 7/8″ Seal Diameter

Note: Transmission slip yokes are manufactured with various U-Joint Series. It is important to match Horsepower and Torque requirements to U-Joint Series. For aftermarket transmission applications usually a spline count and seal diameter will identify slip yoke required.

If Pinion Yoke has Placement tabs that retain the U-Joint, measure inside tabs. See Diagram D.

If Pinion Yoke does not have Placement Tabs that retain U-Joint, measure from flat of yoke inside to inside. See Diagram E.

If 4 bolt Flange is used on pinion, measure Pilot Diameter and center to center diagonally bolt hole to bolt hole. See Diagram L.

Universal Joint Size. There are hundreds of U-Joint sizes or “Series” to accomodate many different applications of power and desired longevity for your automotive, 4×4 truck or auto racing requirements, these 4 series of joints cover most needs.

1310 Spicer Series: 1 1/16″ Cup Diameter (Dim C – Diagram A) 3 7/32″ length (Dim B – Diagram A) Certain Ford applications have 2 cups 1 1/8 Diameter. Appropriate horse power range is up to 500 in circle track or road racing, small tire drag racing and 4×4. Also available: Performance Dynamic Cryo Joint.

1330 Spicer Series: 1 1/16″ Cup Diameter (Dim C – Diagram A) 3 5/8″ length (Dim B – Diagram A) Certain Ford applications have 2 cups 1 1/8 Diameter. Slightly stronger than 1310, Used in 5.0 Mustangs. Also available: Performance Dynamic Cryo Joint.

3R Saginaw Series: 1 1/8″ Cup Diameter (Dim C – Diagram A) Retained with internal clip 2 5/8″ (Dim B – Diagram A). Most common GM joint. Horse power range up to 700 in road racing and circle track. Solid drag racing U-Joint can accomodate most sportsman classes. Also available: Performance Dynamic Cryo Joint.

1350 Spicer Series: Manufactured with OEM tolerances and treated with our Cryogenic Process to yeild the strongest U-Joint available. For drag racing applications a solid non-lube design U-Joint is recommended because of the tremendous initial shock load, or short duration of high torque the joint must be able to withstand.

If PST is supplying you with transmission slip yoke, Pinion yoke and driveshaft yoke measure Dim W. See Diagram N.

If PST is supplying you with transmission slip yoke and driveshaft measure Dim X. See Diagram N.

2 Piece driveshafts use Dim Y + Z. See Diagram N.